BusinessCompetency

ChemOptics supplies electronic materials for semiconductor and devices

for optical communication for future advanced industries.

We also provide foundry services to support R&D

and process validation for photonic semiconductor technologies.

Semiconductor Material

Photoresist

Photoresist (PR) is a type of photosensitive liquid that undergoes chemical changes in response to light, and it is a key material in the exposure process, which uses light to etch circuit shapes onto wafers during semiconductor manufacturing.

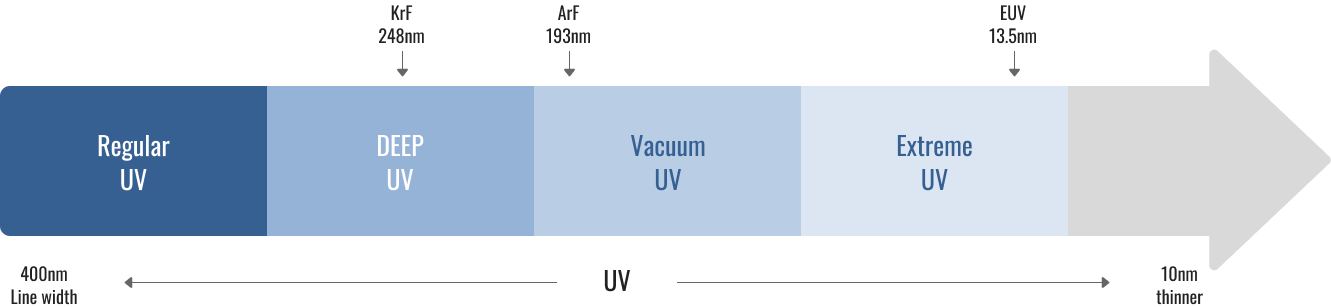

There are different types of light sources used for exposure, depending on the wavelength of the light: extreme ultraviolet (EUV, 13.5nm), argon fluoride (ArF, 193nm), and krypton fluoride (KrF, 248nm). The shorter the wavelength, the finer the circuit line width.

EUV PR (13.5nm)

EUV has the advantage of maximizing resolution with shorter wavelengths and can be implemented with fewer patternings, which dramatically reduces the number of processes.

EUV PR is divided into chemically amplified (CAR, organic) and non-chemically amplified (Non-CAR, inorganic) forms, and ChemOptics is conducting R&D on customized PR materials.

ArF PR (193nm) & KrF PR (248nm)

DUV is a technology that has been used for a long time and has accumulated know-how and high reliability, and its advantage is that exposure equipment is inexpensive and productive.

Chemoptics supplies poly(hydroxystyrene)-based and acrylic polymer resins of various compositions among PR materials composed of polymer resin, photoacid generator (PAG), and base to suit customer applications.